The wire rope is very important during using suspended scaffolds.And before using suspended scaffolds,the head of wire rope must be dealed with.

Before dealing

Before dealing

After dealing

After dealing

From the above two images,we can see that every branch of wire rope is independent just after being cut.So the wire rope will be blocked in the hoist of suspended scaffolds if not being dealed with.

But after being dealed with,the branches of wire rope will melted into a whole with a smooth surface.So at that time,the wire rope can go through the hoist smoothly with no risk.

Below is the processing method:

1. The preparation tools

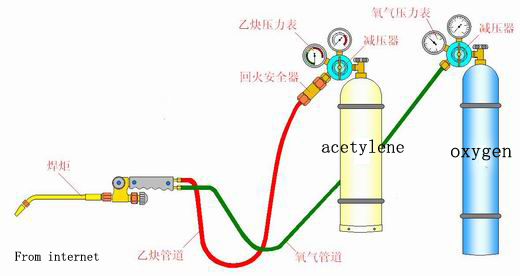

1)Gas welding equipment

The high-pressured acetylene mix the high-pressured oxygen and burn,which result high temperature,then melt the head of wire rope.

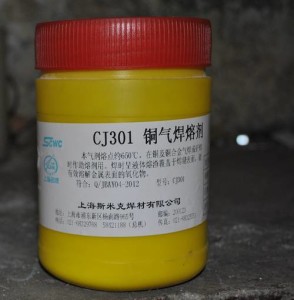

2) Welding flux

The melting point of this is 650 degree.And when welding, it will change into liquid, cover the surface of welding seam,then effectively melt the oxides which is on the surface of wire rope.

3) Wheel machine

The wheel machine can used to rub the wire ropes.

2.Operation steps are as below:

(1)

The wire ropes needed to be put one by one.Put the Welding flux into a iron cup and prepare an iron rod to dip some melding flux. Open the melding machine,fire the heads of wire ropes in advance.

(2)

Prepare an iron rod to dip some melding flux.

(3)

Dip some melding flux to the head of wire rope,at the same time fire it,then some sparks will appear.After dealing like this,wait for wire ropes cooling down.Then we need to rub the wire ropes.

(4) Rub on the two sides of wire rope

Rub on the two sides of wire rope

(5) Rub the cross-section of wire rope.

Rub the cross-section of wire rope.

(6)Below is final result.

Of course there is also a kind of wire rope welding machine which is more automatic.

The pricinple of this machine is like that: Using the current heat effect,using large current go through the wire rope,then get great heat in some cross-section.This can make the wire rope broken in a short time.